Hot melt valves

Reuther-Systems offers innovative hot melt application valves for fast, intermittent or continuous adhesive application. A variety of different single and multiple heads apply hot melt adhesive precisely using dot, line, surface or spray methods. Robust manual hot melt glue guns, electro-pneumatic valves or electric valves process hot melt adhesives on wood, paper, cardboard, plastic and non-woven materials, among others.

Hot melt valves

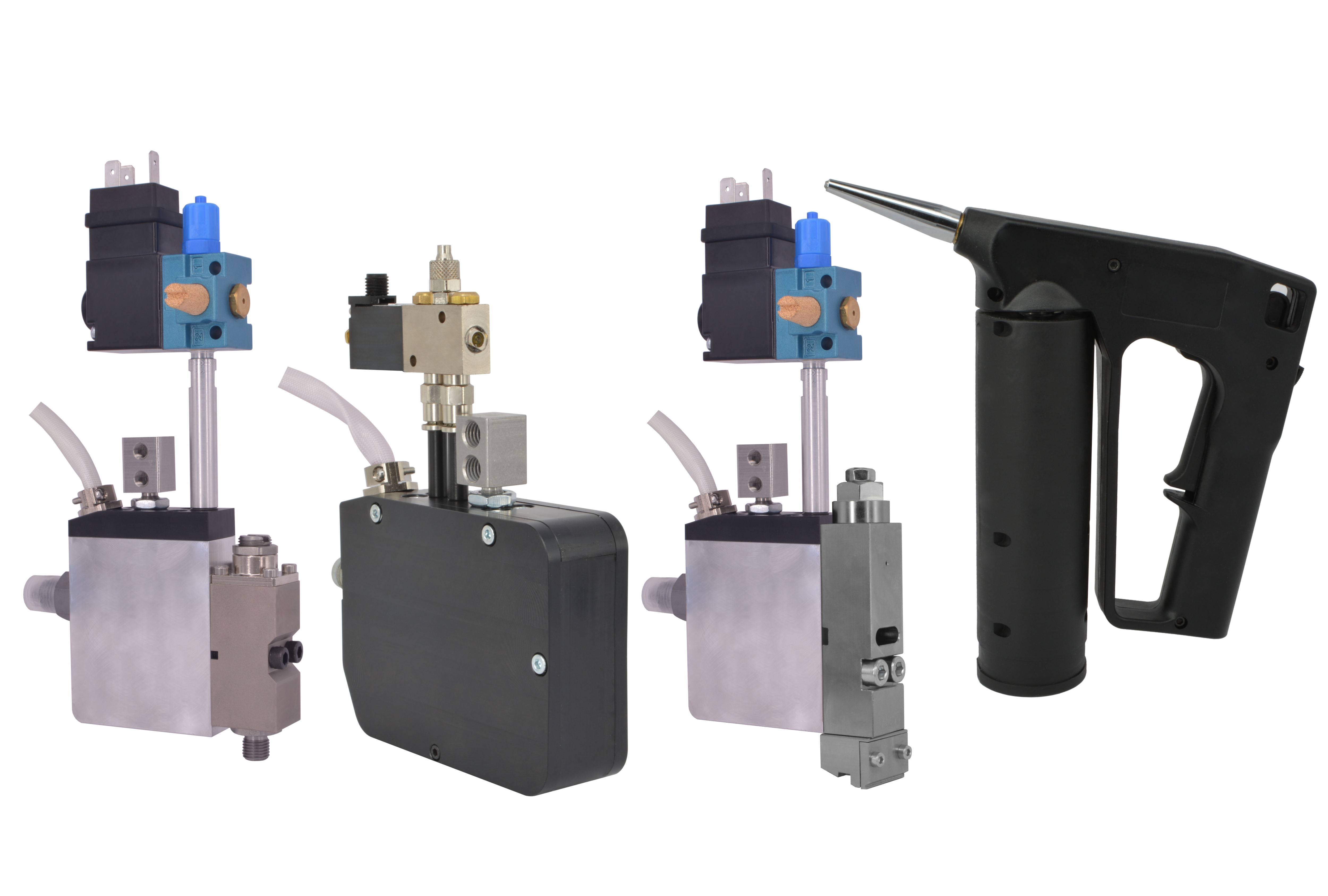

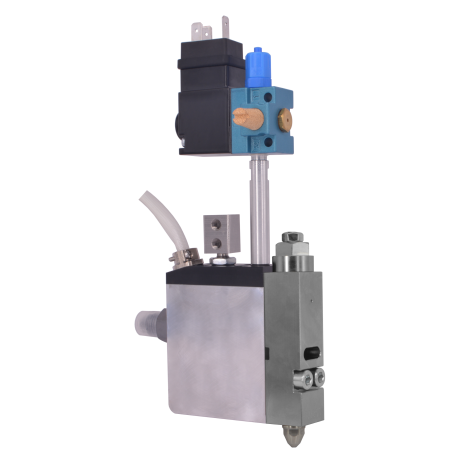

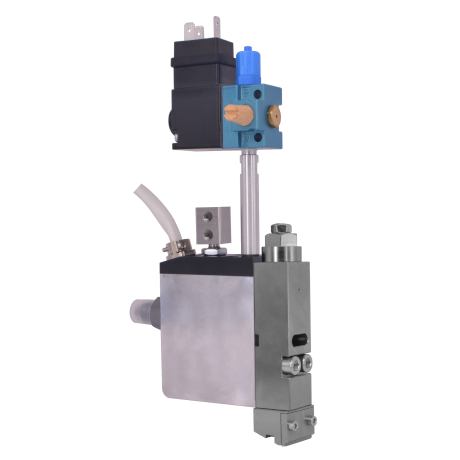

Type HM-90X

- Air-opening and spring-closing valve

- Fast Switching Times

- Self-cleaning needle

- Integrated glue filter to reduce nozzle blockages

- Available in various nozzle diameters

- 24V DC or 230V AC solenoid valves

- Available with short or long nozzle design

- Stable and robust design

- Narrow design (width: 25 mm)

Hot melt valves

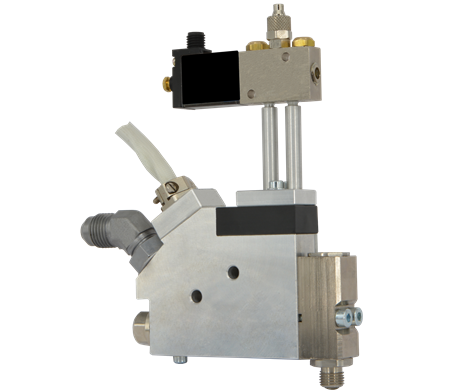

Type HM-Mikro

- Air-opening and air-closing valve

- Very fast switching times

- Integrated glue filter to reduce nozzle blockages

- Various nozzle types can be connected

- 24V DC or 230V AC solenoid valves

- Available with short or long nozzle design

- Stable and robust design

Hot melt valves

Special solutions

- Order widths up to 2500mm

- Coating heads for spray, area, point, or Bead application

- Up to 110 modules can be controlled individually or simultaneously

- Integrated glue filter to reduce nozzle blockages

- 24V DC or 230V AC solenoid valves

Hot melt valves

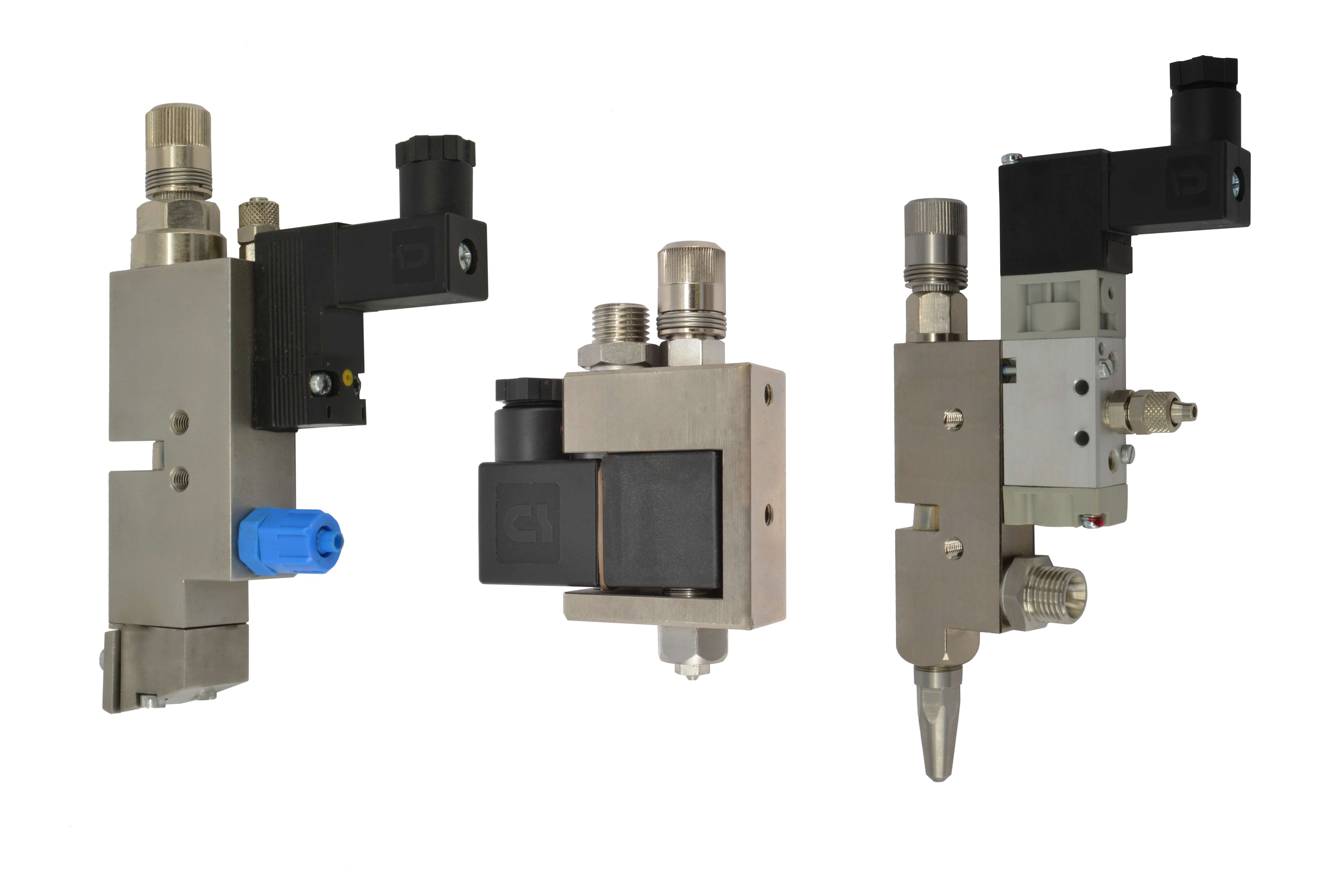

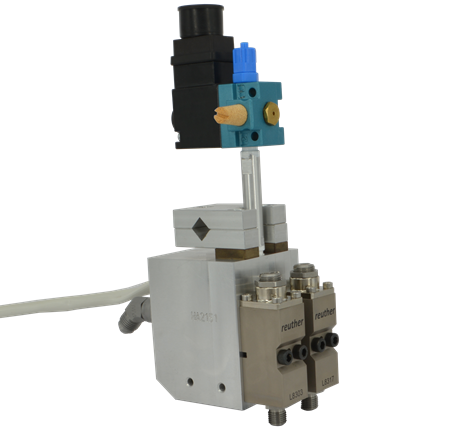

Type HM900-FL20

- Electro-Pneumatic Hot Glue Valve

- Air-opening and spring-closing valve

- Unique adjustable coating width up to max. 20mm

- Fast Switching Times

- Self-cleaning needle and nozzle closure

- Integrated glue filter to reduce nozzle clogging

- 24V DC or 230V AC solenoid valves

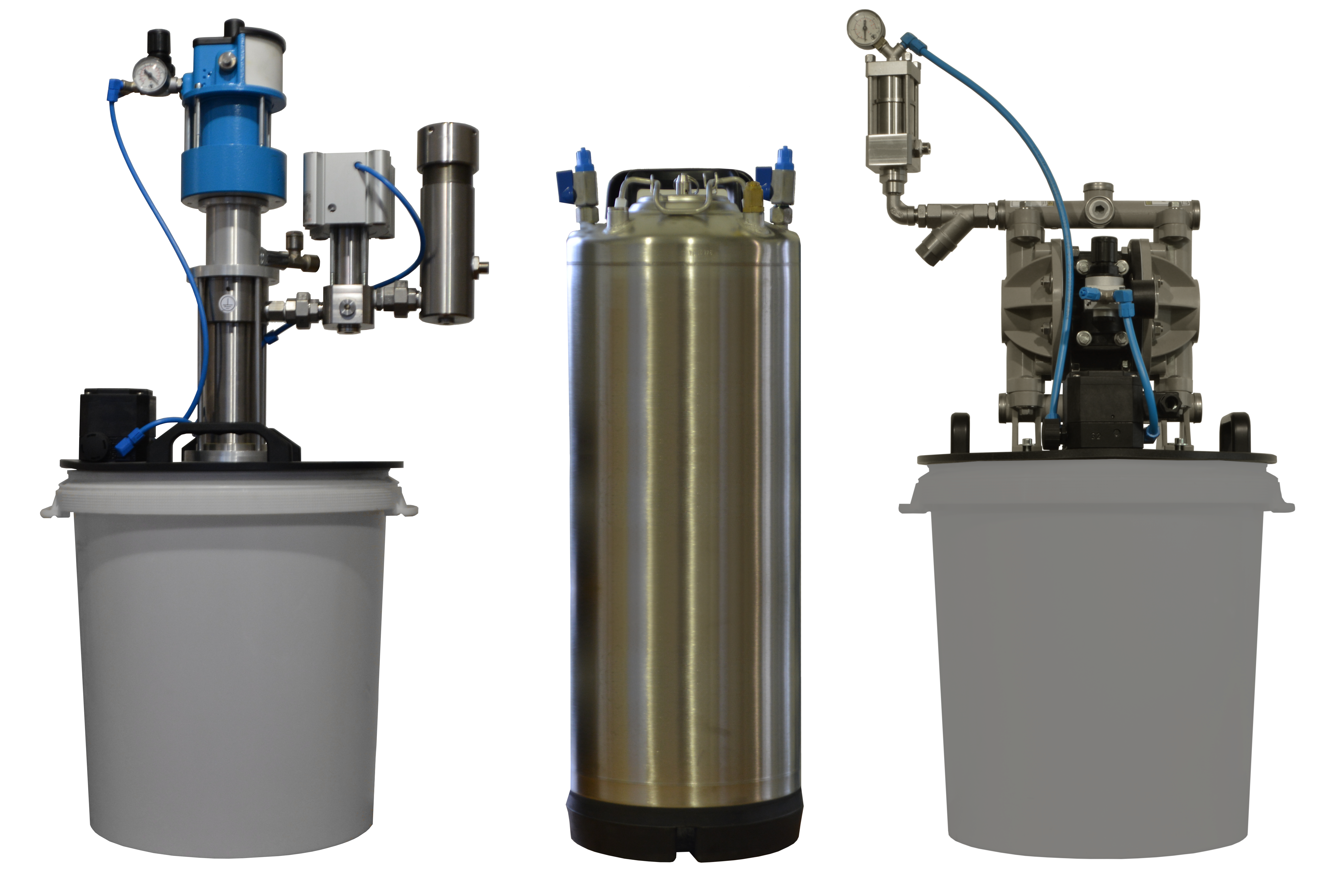

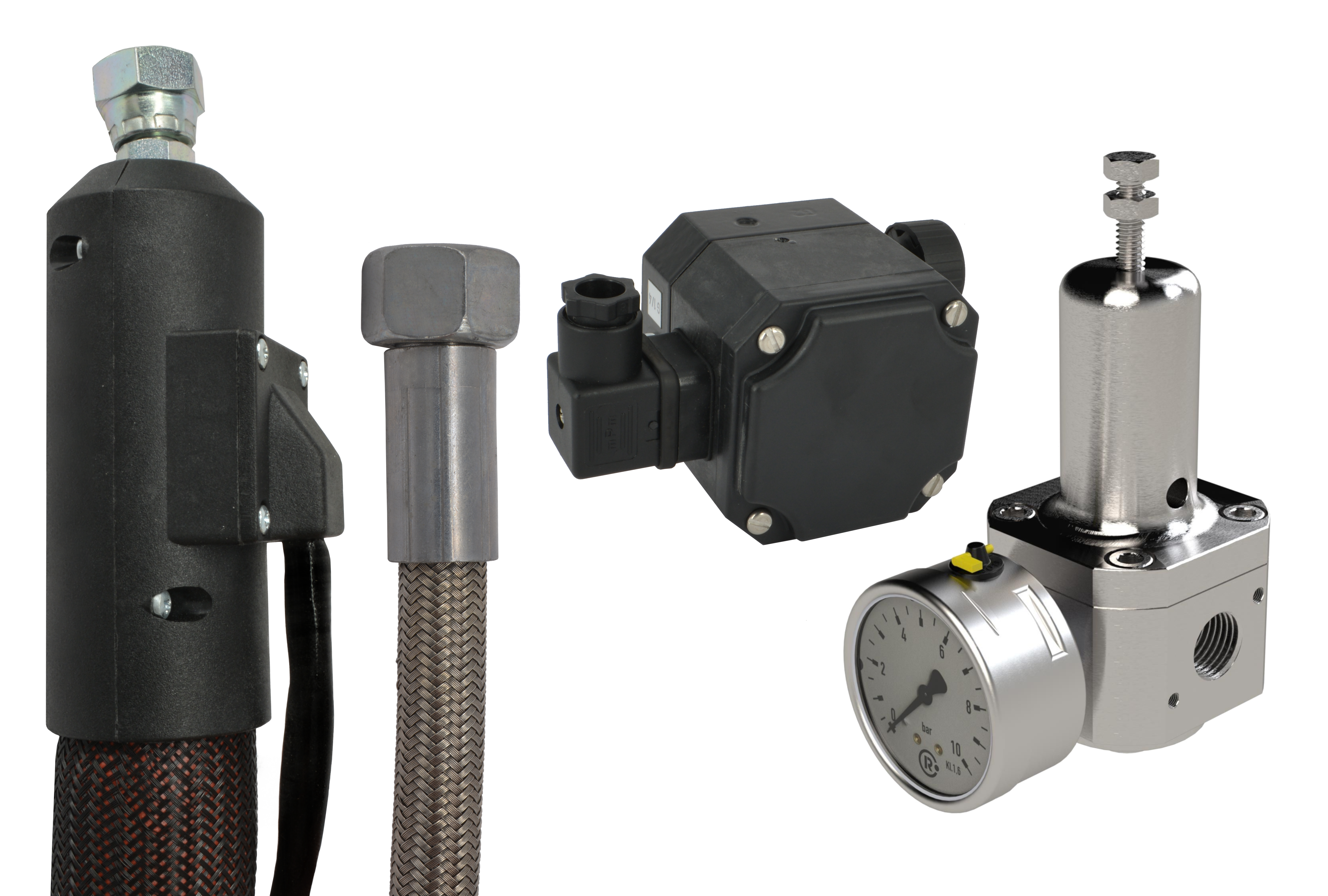

Hand gun PR3000

- For dot and bead application

- Insulated Hose Connection

- Also available as a spray version